What are Hockey Sticks Made Of

Imagine flying an old wooden biplane into battle. On the horizon you see your enemy in a brand new F-35 fighter jet. How are you supposed to compete when your enemy is using a tool that is more advanced than yours in every way? That’s what it’s like showing up to the rink with a wooden stick these days. Technology has come a long way and hockey sticks are no exception. So, what are hockey sticks made of today? Long gone are the days of birch and maple, since replaced by high tech composites. Sometimes we take for granted how much engineering goes into a modern hockey stick. This article will show you what materials sticks are made out of and how those materials affect the performance of the stick.

Modern hockey sticks are made of fiber reinforced plastic and foam. Fiber reinforced plastic employs the same concept as concrete with rebar. The fiber has high tensile strength and the polymer has high compressive strength. Each material’s strength compensates for the other’s weakness. This creates a durable, high performance material. The best sticks are made with Carbon Fiber Reinforced Polymer. Carbon Fiber Reinforced Polymer is a fiber reinforced plastic made using epoxy resin and carbon fiber. Cheaper sticks incorporate fibers like fiberglass, saving cost at the price of performance. The three main components of a quality hockey stick are epoxy resin, carbon fiber, and foam.

Epoxy

Epoxy resin is the glue that holds a stick together. It is a liquid that hardens into a plastic by a chemical reaction called curing. The resulting plastic is called epoxy and has many desirable properties such as a high strength to weight ratio, high adhesion, water resistance, heat resistance, and chemical resistance. There are many different epoxy resins all having different properties. Epoxy resins are chosen for specific applications based on their properties. If an epoxy resin with the characteristics to perform a task does not exist then an epoxy with those characteristics can be designed and created. Epoxy is widely used and has many applications including household, aerospace, marine vessels, electronics, and infrastructure.

Carbon

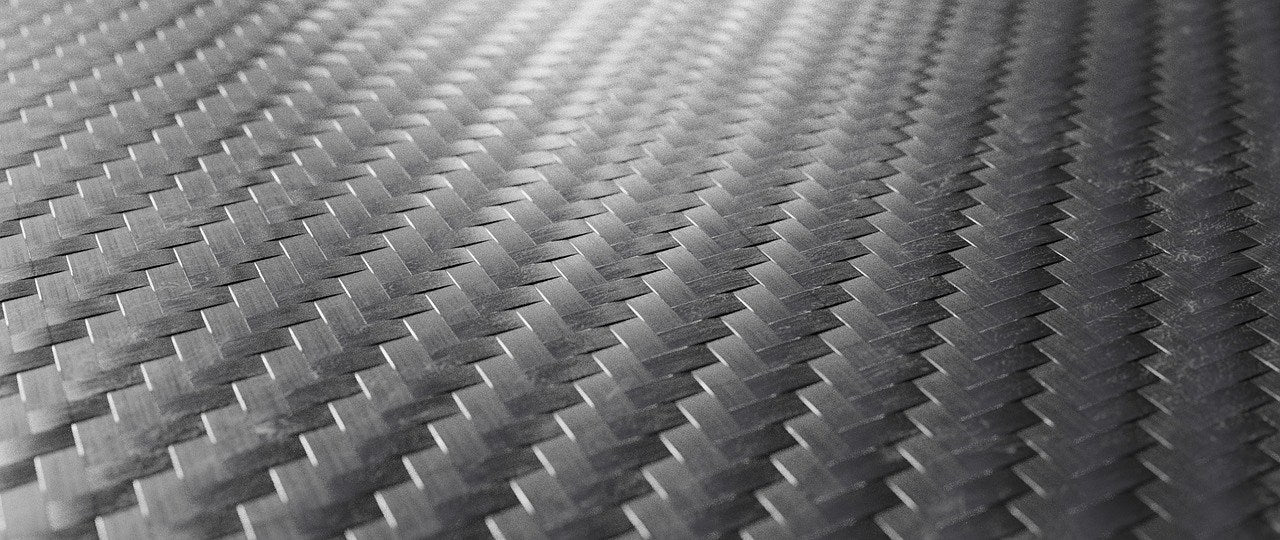

Carbon fibers make up the structure of the stick. Carbon fibers are threads that are 5-10 micrometers in diameter. The fibers are lightweight, stiff, and have high tensile strength. Thousands of these fibers are bundled together to form what is known as a tow. Carbon fiber tows can be used on their own or woven into carbon fiber cloth.

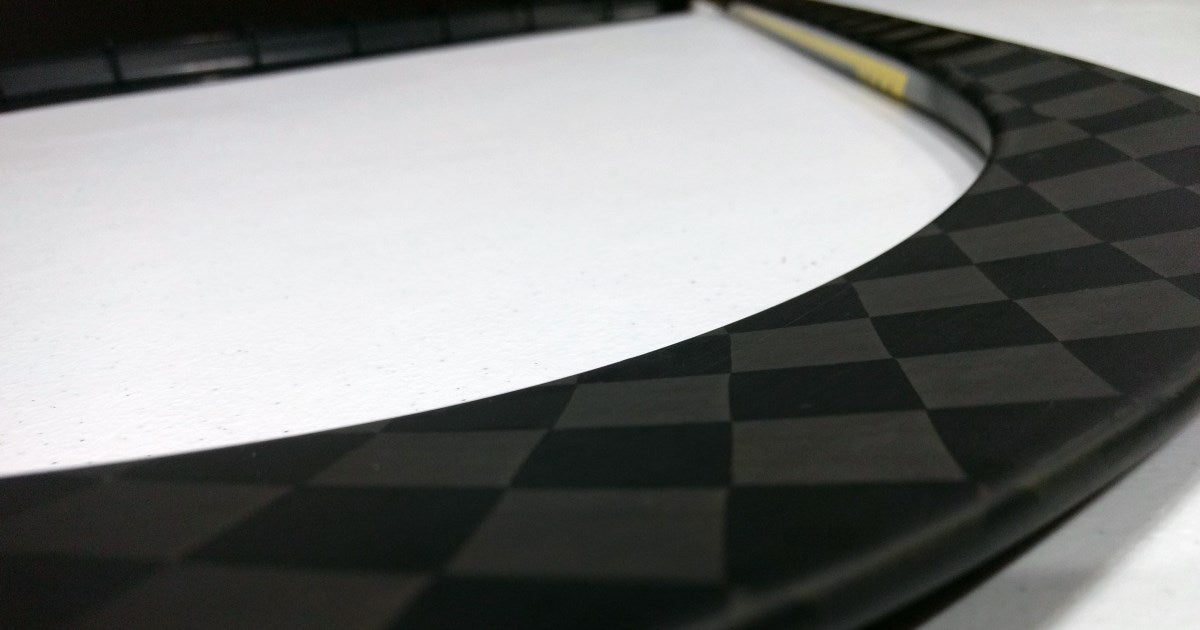

Different styles of weave can give the carbon fiber cloth different characteristics. The most used weaves in hockey sticks are unidirectional and bidirectional. Unidirectional carbon fiber is unwoven and all fibers are parallel. It has the highest tensile strength of any carbon fiber cloth, but only in the direction of the fibers. Bidirectional carbon fiber has its tows woven perpendicular to each other. It has strength in all directions, but the criss-crossing of the fibers reduces the tensile strength in each direction. Bidirectional carbon fiber is typically named after the number of strands of the tow used to weave it: 1k, 3k, 12k, 18k, etc.

Hockey sticks use a special kind of carbon fiber cloth called pre-preg that is coated with partially cured epoxy resin. The partially cured resin coating is easier to work with than liquid resin and reduces the chances of defects like uneven layers and air bubbles.

Foam

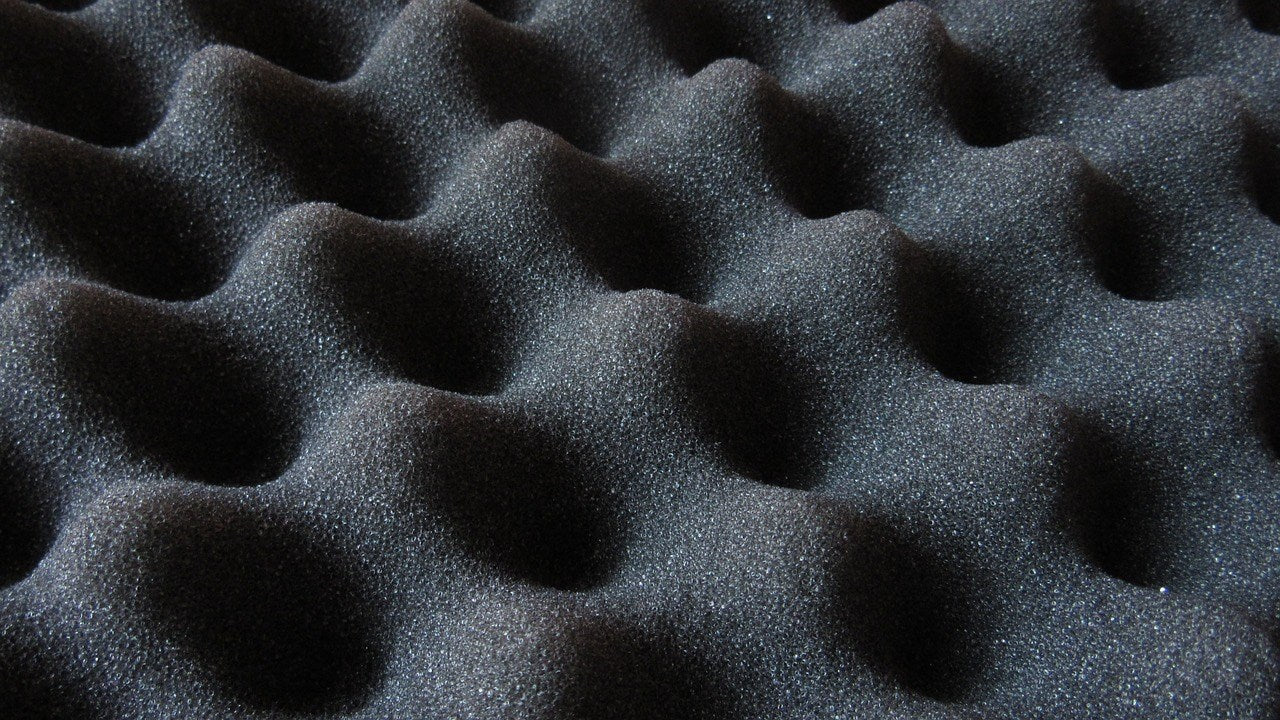

The blade of a hockey stick is primarily made of foam. The foam core is soaked with resin and covered with pre-preg to increase its rigidity. The core of a hockey blade improves the feel for the puck and the pop of the puck off the blade. Different foam cores can give sticks different levels of feel, durability, and performance. The two most used foams are polyurethane(PU) and polystyrene(referred to as epoxy foam). These two foam styles are also the most used surfboard cores. We can learn characteristics of these cores from surfboard builders, and we can apply that knowledge to hockey sticks.

Polyurethane(PU) Foam

Polyurethane is a large family of plastics with many applications in both solid and foam forms. Low end sticks use PU foam to save costs. PU foam blade cores are heavier, softer, and cheaper than epoxy foam blade cores. They give the blade a soft feel, but can make the stick feel blade-heavy. PU foam blades are able to absorb force from the puck without fracturing due to their softness. The weight of the puck while shooting and passing causes a blade to experience elastic deformation. A PU foam blade will experience more deformation due to its softness. It is also slower to return to its original shape. This increased deformation and low elasticity sacrifices both accuracy and velocity. PU foam blade cores use a different resin than the rest of the stick. The different resins don't bond together as well as a single type of resin and make it more likely for a PU foam blade to split apart than an epoxy foam blade.

Epoxy Foam

Polystyrene is a widely used hard plastic in both solid and foam forms. When used in conjunction with epoxy resin it is referred to as epoxy foam. Epoxy foam blade cores are light and stiff. They give the blade a lively feel with more pop than PU foam blade cores. Epoxy foam blades experience less elastic deformation due to their rigidity. They also return to their original shape more quickly after deformation. This low deformation and high elasticity gives the stick more pop and accuracy. The stiffness also has a downside. Due to the stiffness of epoxy foam, the blade core will develop microfractures from contact with the puck. Over time these microfractures reduces the pop of the stick and makes it feel 'dead'. Epoxy foam blade cores use the same epoxy resin that holds together the rest of the stick. The single resin allows the core to bond better to the rest of the stick creating a solid and durable connection. The performance benefits of epoxy foam outweigh its disadvantages.

At Flex Hockey we value performance over profits. Our sticks use an all carbon fiber construction with an epoxy foam blade core. High quality materials gives our sticks top of the line performance and feel, but they're a fraction of the cost. Here's more info on our sticks.